Design of the production machine

Mission of MEIKODO

The mission of Meikodo is to “make what customers want”.

Based on its mission, Meikodo's technical development team has been building a system that performs everything from conception, mechanical design, electrical design, component processing, and assembly in-house over the years. The reason is to meet as many customer requests as possible. We have been working day and night to expand the processing area as much as possible.

The technology development team, which has designed and developed various machines to produce a wide variety of needles, is now producing machines for manufacturing not only needles but also various wire rod products and metal products. We also design molds for molding using flow analysis software.

Based on its mission, Meikodo's technical development team has been building a system that performs everything from conception, mechanical design, electrical design, component processing, and assembly in-house over the years. The reason is to meet as many customer requests as possible. We have been working day and night to expand the processing area as much as possible.

The technology development team, which has designed and developed various machines to produce a wide variety of needles, is now producing machines for manufacturing not only needles but also various wire rod products and metal products. We also design molds for molding using flow analysis software.

Design of Machines

① Planning of development schedule

When a development project occurs, a “DR Design Review” will be held.

The details of the project (shape, sales volume, desired delivery date, etc.) will be heard from the customer, and the technical development team will coordinate basic information on the product.

In addition, we also design the process in the DR, identify manufacturing problems and consider solutions.

② Concept design

If a development project requires the launch of new equipment, create a rough estimate for the equipment based on the concept of manufacturing equipment.

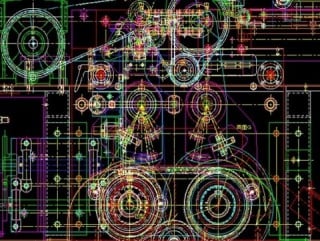

③ Machine design

We interview customers with detailed product specifications, quantities and delivery dates, and decide on a machine concept that can meet the customer's wishes.

Using mechanical know-how accumulated over 70 years by Meikodo, we will perform mechanical design using 2D / 3D CAD and electrical control design using a sequencer.

④Assembly and trial operation of equipment

We procure the necessary parts for the designed equipment or process and manufacture it in-house to assemble the manufacturing equipment

After assembling the equipment, a trial product is manufactured and evaluated by the customer while performing a trial run.

If the evaluation is good, we will make a limit sample and start full-scale preparation for mass production.

The process from design to trial run is repeated until stable quality and reliability can be confirmed.

⑤ Mass production

Even after the start of mass production, we will always look for improvements in the manufacturing process and work to improve productivity and quality.

When a development project occurs, a “DR Design Review” will be held.

The details of the project (shape, sales volume, desired delivery date, etc.) will be heard from the customer, and the technical development team will coordinate basic information on the product.

In addition, we also design the process in the DR, identify manufacturing problems and consider solutions.

② Concept design

If a development project requires the launch of new equipment, create a rough estimate for the equipment based on the concept of manufacturing equipment.

③ Machine design

We interview customers with detailed product specifications, quantities and delivery dates, and decide on a machine concept that can meet the customer's wishes.

Using mechanical know-how accumulated over 70 years by Meikodo, we will perform mechanical design using 2D / 3D CAD and electrical control design using a sequencer.

④Assembly and trial operation of equipment

We procure the necessary parts for the designed equipment or process and manufacture it in-house to assemble the manufacturing equipment

After assembling the equipment, a trial product is manufactured and evaluated by the customer while performing a trial run.

If the evaluation is good, we will make a limit sample and start full-scale preparation for mass production.

The process from design to trial run is repeated until stable quality and reliability can be confirmed.

⑤ Mass production

Even after the start of mass production, we will always look for improvements in the manufacturing process and work to improve productivity and quality.

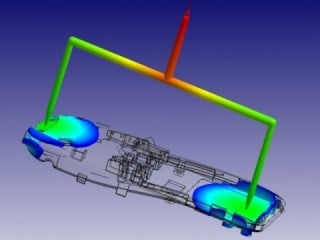

The flow analysis

In the case of a resin molded product development project, it is possible to grasp the type of resin, gate position, number of workpieces, mold temperature, mold design, etc. using flow analysis software before manufacturing molds is.

Because injection molds are quite expensive, risk can be avoided by knowing the information in advance.

Because injection molds are quite expensive, risk can be avoided by knowing the information in advance.